Publicidad

Enlaces rápidos

Franklin Electric Co., Inc.

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiantPump.com

CustomerService-WTS@fele.com

Recognized under the component program of Underwriters Laboratories.

Reconnaître sous le programme de composant de Underwriters Laboratoires.

Reconocido debajo el programa de componente de Underwriters Laboratorios.

INTRODUCTION

EN

The 2E-NYS pump is designed for submerged use only. Its motor is hermetically

sealed in a diecast aluminum housing, which is oil-filled for heat transfer and

permanent lubrication. It is intended to pump unheated metal parts-cleaning

solvent that is UL classified as PJQU as described in the Gas and Oil Equipment

Directory. These are refined petroleum distillates that are free from the tendency

to heat spontaneously. They have a closed cup flash point not lower than 100

degrees F. These are typical fluids that are compatible with the pump materials

(except the power cord.) See Installation step 1.

NOTE: This pump is intended for use only in parts cleaners listed by

Underwriters Laboratories. The combination of the fluid pumped, the pump, and

the design of the parts washer will determine if additional safety devices, such

as a low liquid level cut off, are required. Refer to parts washer manufacturer's

instructions to see if this is required.

SAFETY GUIDELINES

Before servicing the pump, see solvent and equipment manufacturer's

instructions for further safety information and possible hazards.

Follow all local electrical and safety codes, as well as the National Electrical

Code (NEC) and the Occupational Safety and Health Act (OSHA).

This pump must be properly grounded while in use to protect the operator from

electrical shock.

The pump must be protected by a ground fault circuit interrupter (GFCI) when

pumping water-based solutions.

Always disconnect power source before working on the pump. If the power

disconnect point is out of sight, lock in the open position and tag to prevent

unexpected application of power.

Do not attempt to make your own parts cleaners.

The low flash point of these combustible liquids does present a moderate fire

hazard. Operating the pump fully submerged offers added protection from fire

risk. For other solvent handling precautions, consult the material safety data

sheet (OSHA-20 form, or equivalent) for the solvent used.

Use only UL-approved metal parts cleaning solvents. The use of fluids such as

gasoline and lower flash point solvents is dangerous and may cause explosions

or fire. Solvents other than UL-approved metal parts cleaning solvents will void

the warranty of this product.

NOTE: Cover to be designed to close in case of fire •

NOTE: En cas d'incendie, le couvercle se ferme •

NOTA: Cubierta diseñada para cerrarse en caso de

incendio

Fluid level •

Niveau du liquide

• Nivel de líquido

1/4" FNPT coupling (discharge) • Raccord MNPT 1/4 po

(refoulement) • Acoplamiento de 1/4" MNPT (descarga)

Submersible Pump For Parts

Washers

Pompe Submersible Pour Des

Lessiveuses De Parties

Bomba Sumergible Para

Lavadoras De Partes

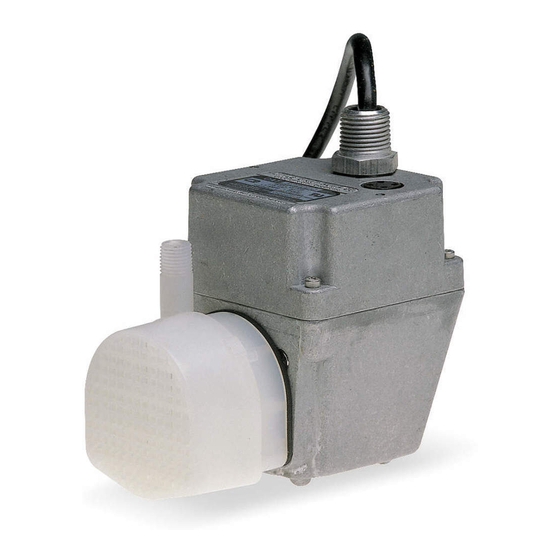

Model 2E-NYS

Wash basin • Bassin de

lavage • Cubeta de

lavado

Suction inlet .................................................................. Hooded, approx. ½" I.D.

Discharge outlet .......................................................................... 1/4" NPT (male)

Cord type ............................................................................................18/3 (SJTO)

Pipe connector around cord .......................................................1/2" NPT (male)

Pump housing (volute) ................................................................................ Nylon

Motor housing ................................................... Die-cast aluminum (unpainted)

Impeller ....................................................................... Nylon (with S.S. bushing)

Pump screen .................................................................................... Polyethylene

Pump shaft seal ..........................................................................................Viton®

Motor shaft .............................................................................................. 440 S.S.

Volute & pump screws ....................................................... 410 S.S. or 18-8 S.S.

Overall dimensions ................................................4-3/4" H x 5-1/2" L x 3-1/2" W

Maximum fluid temperature .........................................................................100° F

WARNING: Do not allow the pump's power cord to come in contact with

solvent. The solvent may damage the cord insulation, causing the cord to

become stiff or lower its insulating properties. The pump is supplied with a

three-conductor power cord. The third conductor is to ground the pump to

prevent possible electrical shock hazard.

1. Seal the power cord inside of liquid-tight, ½" NPT steel intermediate metal

conduit. Use caution to ensure that cord will not be nicked or cut.

2. Consult pump nameplate data for proper voltage and frequency. Please

note, the black (or brown) and white (or blue) wires are live and the green

(or green/yellow) wire is ground.

3. Be sure that the pump is fully submerged in the cleaning solvent.

4. The pump power supply cord must be connected to a properly grounded,

grounding-type receptacle.

WARNING: UNPLUG THE UNIT BEFORE ATTEMPTING TO SERVICE OR

REMOVE ANY COMPONENT!

CAUTION: This unit is permanently lubricated. Oiling is not required. Do not

open the sealed portion of the unit or remove housing screws.

Periodic cleaning of the pump parts will prolong the life and efficiency of the

pump. Refer to Fig. 2 for the assembly and disassembly of the pumping head.

1. Lightly clean any corrosion or debris that may clog the impeller. Use a brush

and penetrating oil and lightly scrape. NOTE: Do not allow sediment from

parts being washed to build up and restrict the flow of fluid into the pump.

2. Turn the impeller by hand to make sure it is free. If it does not turn or if pump

is tripping circuit breaker, or not operating properly after cleaning, return to

Little Giant or its authorized service center. Do not attempt repairs yourself.

If it does turn, replace volute and re-install into parts washer.

3. Be certain power cord is protected from solvent and has no nicks or cuts.

3-prong plug to properly grounded circuit • Fiche

à 3 branches. Raccorder à un circuit correctment

mis à la terre. • Clavija de tres puntas a un circuito

debidamente conectado a tierra

Liquid-tight steel intermediate metal

conduit (1/2" MNPT) • Conduit en acier

étanche au liquides (1/2 po MNPT) •

Conducto de metal intermedio de acero

impermeable (1/2" MNPT)

1/2" FNPT coupling •

Raccord 1/2 po FNPT •

Conector FNPT de 1/2"

Male conduit fitting • Raccord de

conduit (mâle) • Acoplamiento

del conducto macho

Model 2E-NYS pump •

Pompe modele 2E-NYS •

Modelo bomba 2E-NYS

TYPICAL INSTALLATION • INSTALATION TYPE •

INSTALACION TIPICA

SPECIFICATIONS

INSTALLATION

MAINTENANCE

FIGURE 1

Publicidad

Resumen de contenidos para Franklin Electric Little Giant 2E-NYS

- Página 1 Discharge outlet ................1/4” NPT (male) Pompe Submersible Pour Des Cord type ....................18/3 (SJTO) Lessiveuses De Parties Pipe connector around cord ............1/2” NPT (male) Franklin Electric Co., Inc. P. O. Box 12010 Pump housing (volute) ................Nylon Bomba Sumergible Para Oklahoma City, OK 73157-2010 Motor housing ...........

- Página 2 La bomba 2E-NYS está diseñada para ser usada solamente en inmersión. El UL. L’utilisation de liquides tels que l’essence et autres solvants au point éclair motor de la bomba Little Giant 2E-NYS está sellado herméticamente en una caja encore plus faible est dangereuse et risque de causer des explosions ou des de aluminio fundido a presión llena de petróleo para la transferencia de calor...

- Página 3 MANTENIMIENTO en la posición abierta y agréguele un aviso para evitar la aplicación repentina de la corriente. No intente fabricar sus propios limpiadores de piezas. El bajo punto de inflamación de estos líquidos combustibles presenta un peligro ADVERTENCIA: ASEGÚRESE QUE LA BOMBA ESTÉ DESCONECTADA de incendio moderado.

- Página 4 ..... . . 1.888.572.9933 Para la ayuda técnica, por favor póngase en contacto ..1.888.956.0000 Form 993633 - 03/2008 www.LittleGiantPump.com ©2008 Franklin Electric Co., Inc. CustomerService-WTS@fele.com Little Giant® is a registered trademark of Franklin Electric Co., Inc.