Publicidad

Idiomas disponibles

Idiomas disponibles

Enlaces rápidos

G e n e r a l i n f o r m a t i o n :

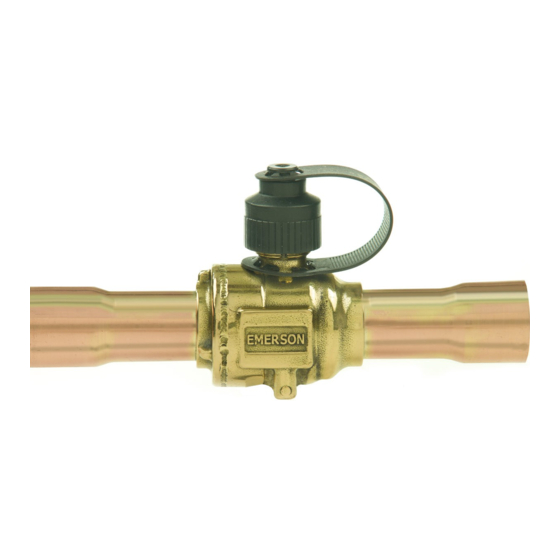

The BVE/BVS series of Bi-directional Ball valves are

designed for general use in isolating suction, discharge

and liquid line pipe-work during maintenance

shutdown periods.

S a f e t y i n s t r u c t i o n s :

• Read installation instructions thoroughly. Failure

to comply can result in device failure, system

damage or personal injury.

• According to EN 13313 this product is intended

for use by personnel having the appropriate

knowledge and skill.

• Before opening any system make sure pressure in

system is brought to and remains at atmospheric

pressure.

• Do

not release any

refrigerant into the

atmosphere!

• Do not exceed the specified maximum ratings for

pressure and temperature.

• Do not use any other fluids without prior approval

of EMERSON. Use of fluids not listed could result

in Change of hazard category of product and

consequently change of conformity assessment

requirement for product in accordance with

European

Pressure

Equipment

2014/68/EU.

• The attached strap (Fig. 3) contains important

valve data. Do not remove because of warranty

and traceability reasons.

• Do not connect on BVS Schrader connection any

safety pressure switches or other control devices

M o u n t i n g l o c a t i o n :

• The BVE/BVS valve may be installed in any position

which allows access to remove the stem cap. The

valves are bi-directional.

• Locate the BVE/BVS as close as possible to the

section of pipe-work to be isolated. This will reduce

the amount of refrigerant to be recovered during

future maintenance of the system.

T e c h n i c a l D a t a :

Type:

Connection, DN

Max. allowable pressure PS

Medium temperature TS

Fluid group (PED)

Hazard category (PED)

Medium compatibility

Material

Markings

Emerson Climate Technologies GmbH

Am Borsigturm 31 I 13507 Berlin I Germany

Operating instructions

Ball Valves Series BVE / BVS

I n s t a l l a t i o n :

• Do not remove seal caps until ready for installation

in order to minimize entering of moisture and dirt.

• Avoid damaging the connections!

• For BVS version do not mount schrader valve and

cap before brazing.

• For installing the Schrader valve core use torque

0.4 – 0.5 Nm. Standard torque tool for Schrader

valve should be used.

• For panel mounting see dimension of holes in Fig. 4.

B r a z i n g :

Warning:

Ensure valve is in the fully open position before brazing

(see Fig. 2a). Failure to do so could cause damage to

internal components.

• Perform and consider the brazing joint as per

EN 14324.

• Before and after brazing clean tubing and brazing

joints.

• Minimize vibrations in the piping lines by appropriate

solutions.

• To avoid oxidization, it is advised to purge the system

with an inert gas such as nitrogen while brazing.

• Do not exceed the max. body temperature of 120°C!

• To avoid overheating it is advised to make the joint at

Directive

one end cool the device completely before repeating

the procedure on the other end connection.

• For BVS version install schrader valve and schrader

valve cap after cooling down of the ball valve.

P r e s s u r e T e s t :

After completion of installation, a pressure test must be

carried out as follows:

̵ according to EN 378 for systems which must

comply with European pressure equipment

directive 2014/68/EU.

̵ to maximum working pressure of system for other

applications.

Warning:

• Failure to do so could result in loss of refrigerant

BVE- / BVS-... ≤ 28 mm

1/4" (6 mm) ... 1-1/8" (28 mm)

–40°C ... +120°C (short term +150° C) / –40°F ... +250°F (short term +300°F)

I + II

SEP

A1:

R134a, R404A, R407C, R450A, R452A, R448A, R449A,

R507, R513A, R410A

A2L: R32, R452B, R454B, R454A, R454C, R455A, R1234ze,

R1234yf

SA5312) (A2L pending)

(No.

www.climate.emerson.com/en-gb

and personal injury.

• The pressure test must be conducted by skilled

personnel with due respect regarding the danger

related to pressure.

T i g h t n e s s T e s t :

Conduct a tightness test according to EN 378-2 with

appropriate equipment and method to identify leakages

of external joints. The allowable leakage rate must be

according system manufacturer's specification.

O p e r a t i o n :

• The Valve has a built-in stop for the stem and

opening/closing of the valve is clearly indicated as

shown in Fig. 3. Open Valve is shown in Fig. 2a and

closed valve in Fig. 2b.

Note: Never leave the ball position as shown in

Fig. 2c otherwise seat leakage can occur.

• To avoid operation by unauthorized person's valve

can be equipped with a sealable cap which is available

as accessory (see Fig. 5).

• The plastic cap is equipped with an O-Ring. Do not

use any tool to mount the cap. Cap must be closed

hand tight only.

Warning:

If the valve is installed in hot gas discharge line, the

valve has hot surface temperature during operation

of system or short after off-cycle.

D e s i g n c o n s i d e r a t i o n :

The Design pressure marked on this component shall

•

not be less than the installed system working pressure

or less than the values outlined in ANSI/ASHRAE 15

for the charges refrigerant. After charging mark Unit

with refrigerant type and oil type.

For use with refrigerant listed in CAN/CSA B52,

•

ANSI/ASHRAE 34. After charging mark Unit with

refrigerant type and oil type.

BVE- / BVS-...> 32 mm

1-3/8" (35 mm) ... 3-1/8" (79.4 mm)

45 bar / 650 psig

A1:

R134a, R404A, R407C, R450A, R452A, R448A, R449A,

R507, R513A, R410A

A2L: R1234ze

CW617N

(No.

BVE(S)_OI_EN_DE_FR_ES_IT_RU_0421_R11_864091.docx

II

I

acc. PED (2014/68/EU)

SA5312) (A2L pending)

Date: 27.04.2021

Publicidad

Resumen de contenidos para Emerson ALCO CONTROLS BVE Serie

- Página 1 • Do not use any other fluids without prior approval use any tool to mount the cap. Cap must be closed solutions. of EMERSON. Use of fluids not listed could result • To avoid oxidization, it is advised to purge the system hand tight only.

- Página 2 Lötverbindungen sind gemäß EN 14324 Temperatur nicht überschreiten. verwendet werden (siehe Fig. 5) auszuführen. • Es dürfen nur von EMERSON freigegebene • Die Plastikkappe enthält einen O-Ring • Vor und nach dem Löten sind die Lötstellen zu Medien eingesetzt werden. Die Verwendung nicht Abdichtung.

- Página 3 • Ne pas utiliser un autre fluide que ceux indiqués capuchon doit être serré à la main uniquement. équipements appropriés. sans l’approbation obligatoire d’EMERSON. • Pour éviter l'oxydation, il est conseillé de purger le Attention: L'utilisation d'un fluide non approuvé peut système avec un gaz inerte comme le nitrogène...

- Página 4 • No use ningún fluido que no haya sido • Limpie los tubos antes y después de realizar la • Para evitar la manipulación inadecuada de la válvula, previamente aprobado por EMERSON. El uso de soldadura. esta puede ser suministrada con un tapón precintable sustancias no aprobadas puede dar lugar a: un •...

-

Página 5: Istruzioni Operative

A2L: R32, R452B, R454B, R454A, R454C, R455A, R1234ze, A2L: R1234ze R1234yf Materiale CW617N PED (2014/68/EU), SA5312) ( A2L) (No. In attesa di Marchio SA5312) ( A2L) (No. In attesa di Emerson Climate Technologies GmbH www.climate.emerson.com/en-gb Date: 27.04.2021 Am Borsigturm 31 I 13507 Berlin I Germany BVE(S)_OI_EN_DE_FR_ES_IT_RU_0421_R11_864091.docx... - Página 6 A2L: R32, R452B, R454B, R454A, R454C, R455A, R1234ze, A2L: R1234ze R1234yf Материал CW617N PED (2014/68/EU), SA5312) ( A2L) (№ ожидает Маркировка: SA5312) ( A2L) (№ ожидает Emerson Climate Technologies GmbH www.climate.emerson.com/en-gb Date: 27.04.2021 Am Borsigturm 31 I 13507 Berlin I Germany BVE(S)_OI_EN_DE_FR_ES_IT_RU_0421_R11_864091.docx...

- Página 7 1-3/8” / 35mm ODF BVE/S 158 1-5/8” ODF BVE/S M42 42mm ODF BVE/S 218 2-1/8” / 54mm ODF BVE/S 258 2-5/8” ODF BVE/S 318 3-1/8” ODF Emerson Climate Technologies GmbH www.climate.emerson.com/en-gb Date: 27.04.2021 Am Borsigturm 31 I 13507 Berlin I Germany BVE(S)_OI_EN_DE_FR_ES_IT_RU_0421_R11_864091.docx...