Publicidad

Idiomas disponibles

Idiomas disponibles

Enlaces rápidos

MRL100 / 942 / 699Plus

A1- Instruction Manual

Digital load / weight measuring system

A) Multirope MRL100 - list of included parts

Included parts:

N° 2 screws type TE M8 class 8.8 DIN933 (or

ISO 4762-M8-A2), with calibrated length for

rope diameters [C]

N° 1 MultiRope mod. MRL rope sensor [A]

N° 1 Deflection rod [B]

NOTE:

A) The engraved letter [C] screws, is matched

to the following elevator rope diameters:

F: N° 3 ropes, diameter 6,5 mm

F: N° 4 ropes, diameter 6,5 mm

F: N° 6 ropes, diameter 6,5 mm

MultiRope includes only two screws but

additional can be optionally purchased.

OTHER ROPE CONFIGURATIONS

AVAILABLE

B) MRL inner sensor width [A] sets how

many ropes can be inserted.

Standard MRL100 width for ropes is 72

mm, additional widths are available and

MRL100 can be modified for belt tension

measurement or for the characteristics of

Your application.

B) MRL sensor installation on elevator ropes

1) Apply [C] screws to [A] sensor like shown in

picture.

2) Position the MultiRope MRL100 sensor [A] close

to the ropes, parallel to the cabin roof and insert

all ropes in the slot between the screws, without

overlapping them.

Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material. This manual contains information protected by

copyright. No part of this manual may be photocopied, or reproduced in any form, or translated without prior written consent from S2Tech.

S2Tech srl

Via Imperia, 28 Milano – ITALY

Tel: +39 02 8910142 Fax: + 39 02 89124848

When handling the MRL100 transducer, prior installation

on the ropes, avoid any contact of the measurement

element with hard metal parts or tools.

3) When all ropes are between the [C]

screws, apply the [B] deflection rod as

shown in picture.

Distribute the ropes on the available

space inside the MRL100, avoiding any

contact between the ropes and the

threaded part of the screws [C].

e-mail:

info@s2tech.it

www.s2tech.it

4) Screw all calibrated [C] screws in the threaded

[B] deflection rod holes.

5) Evenly position the ropes along the inner

MRL100 sensor slot width.

6) Ropes are to be centered within the sensor width,

for a good quality measurement.

7) Screw [C] screws till they are touching the inner

side of the deflection rod for having a correct

rope deflection. Ropes are slightly bent and are to

touch only the rounded edges of [A] sensor and

[B] deflection rod.

8) Ropes are not to overlap and are to be parallel

between each other.

When [A] Multirope MRL100 sensor is fixed

9)

on the ropes, use the elevator for some runs

with inside the cabin the maximum payload

(also jump in the cabin or make emergency

stops), then calibrate with (MANU procedure)

applying a known weight, in the cabin.

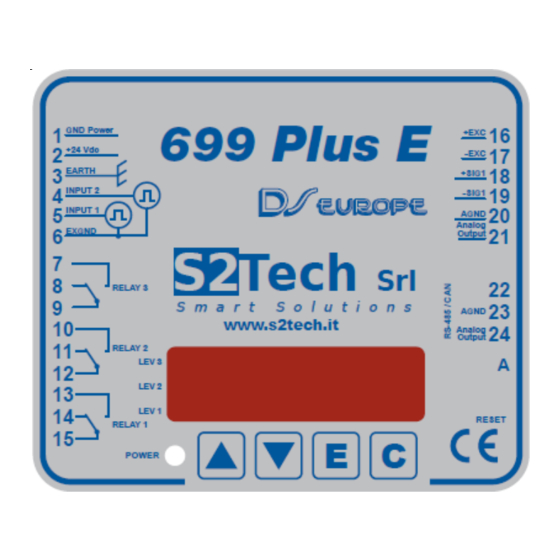

10) ELECTRICAL CONNECTION OF MRL100 SENSOR TO 699 ELECTRONICS

MRL100 rope sensor has a cable with an RJ male connector, fixed at one end that

is to be inserted into a female RJ connector, on the side of the external electronics

type 699-02-RJ.

11) NOTE:

Install the Multirope MRL100 sensor in order to avoid any contact with any part of the lift, like

pulleys or hoistway.

MRL100 sensor cannot be used in case of high friction between the car and the side guiding rails

in the hoistway.

Avoid installing MRL sensor on the ropes on the side that takes the load of the counterweight, as

this branch of ropes does not see the load variation inside the cabin.

Z:\Manuali\LM MRL100_942_699A1\Traduzioni Maggio 2015\LM MRL_942_699A1 V2r7 UK .docx

Version : UK 2r7 dated 25/06/15

Page: 1/4

Correct fixing position.

Publicidad

Resumen de contenidos para S2Tech MRL100

- Página 1 Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

- Página 2 Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

- Página 3 Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

- Página 4 Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

- Página 5 Nota: le informazioni contenute nel manuale possono cambiare senza preavviso. Le informazioni contenute nel presente manuale possono variare senza preavviso. S2Tech declina ogni responsabilità...

- Página 6 Nota: le informazioni contenute nel manuale possono cambiare senza preavviso. Le informazioni contenute nel presente manuale possono variare senza preavviso. S2Tech declina ogni responsabilità...

-

Página 7: Manuale D'istruzione

Nota: le informazioni contenute nel manuale possono cambiare senza preavviso. Le informazioni contenute nel presente manuale possono variare senza preavviso. S2Tech declina ogni responsabilità... - Página 8 Nota: le informazioni contenute nel manuale possono cambiare senza preavviso. Le informazioni contenute nel presente manuale possono variare senza preavviso. S2Tech declina ogni responsabilità...

- Página 9 „Ast“ als kaum sensibel auf die in der Kabine vorhandenen Laständerungen erweist. Anmerkung: Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung geändert werden. Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung variieren. Das Unternehmen S2Tech lehnt jegliche Haftung für eventuelle, hier beinhaltete Fehler und für eventuelle zufällige, direkte oder indirekte Schäden, die aus der Lieferung, dem Betrieb oder der Verwendung dieses Materials herrühren könnten, ab.

-

Página 10: Ce-Konformitätserklärung

4-6(1996) + A1(2001); EN 61000-4-8(1993)+A1(2001); EN 61000-4-11(2004) Anmerkung: Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung geändert werden. Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung variieren. Das Unternehmen S2Tech lehnt jegliche Haftung für eventuelle, hier beinhaltete Fehler und für eventuelle zufällige, direkte oder indirekte Schäden, die aus der Lieferung, dem Betrieb oder der Verwendung dieses Materials herrühren könnten, ab. - Página 11 Messmodalität zurückkehrt (z.B.: MCAL) kann es sein, dass für den Wert der leeren Kabine ein anderes Gewicht als Anmerkung: Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung geändert werden. Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung variieren. Das Unternehmen S2Tech lehnt jegliche Haftung für eventuelle, hier beinhaltete Fehler und für eventuelle zufällige, direkte oder indirekte Schäden, die aus der Lieferung, dem Betrieb oder der Verwendung dieses Materials herrühren könnten, ab.

- Página 12 Analoges Signal Anmerkung: Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung geändert werden. Die in diesem Handbuch beinhalteten Informationen können ohne Vorankündigung variieren. Das Unternehmen S2Tech lehnt jegliche Haftung für eventuelle, hier beinhaltete Fehler und für eventuelle zufällige, direkte oder indirekte Schäden, die aus der Lieferung, dem Betrieb oder der Verwendung dieses Materials herrühren könnten, ab.

- Página 13 Remarque : les informations contenues dans ce manuel peuvent être modifiées sans préavis. S2Tech décline toute responsabilité face à des erreurs pouvant y figurer et face à d’éventuels dommages accidentels, directs ou indirects, dérivant de la fourniture, du fonctionnement ou de l’utilisation...

- Página 14 Remarque : les informations contenues dans ce manuel peuvent être modifiées sans préavis. S2Tech décline toute responsabilité face à des erreurs pouvant y figurer et face à d’éventuels dommages accidentels, directs ou indirects, dérivant de la fourniture, du fonctionnement ou de l’utilisation...

- Página 15 Remarque : les informations contenues dans ce manuel peuvent être modifiées sans préavis. S2Tech décline toute responsabilité face à des erreurs pouvant y figurer et face à d’éventuels dommages accidentels, directs ou indirects, dérivant de la fourniture, du fonctionnement ou de l’utilisation...

- Página 16 Remarque : les informations contenues dans ce manuel peuvent être modifiées sans préavis. S2Tech décline toute responsabilité face à des erreurs pouvant y figurer et face à d’éventuels dommages accidentels, directs ou indirects, dérivant de la fourniture, du fonctionnement ou de l’utilisation...

- Página 17 Nota: la información que contiene este manual puede cambiar sin previo aviso. S2Tech no se asume ninguna responsabilidad de los eventuales errores aquí presentes ni de los posibles daños accidentales directos o indirectos, que deriven del suministro, funcionamiento o uso de este material.

-

Página 18: Instalación Mecánica

Nota: la información que contiene este manual puede cambiar sin previo aviso. S2Tech no se asume ninguna responsabilidad de los eventuales errores aquí presentes ni de los posibles daños accidentales directos o indirectos, que deriven del suministro, funcionamiento o uso de este material. - Página 19 Nota: la información que contiene este manual puede cambiar sin previo aviso. S2Tech no se asume ninguna responsabilidad de los eventuales errores aquí presentes ni de los posibles daños accidentales directos o indirectos, que deriven del suministro, funcionamiento o uso de este material.

- Página 20 Nota: la información que contiene este manual puede cambiar sin previo aviso. S2Tech no se asume ninguna responsabilidad de los eventuales errores aquí presentes ni de los posibles daños accidentales directos o indirectos, que deriven del suministro, funcionamiento o uso de este material.

- Página 21 Примечание: Содержащаяся в данном руководстве по эксплуатации информация может изменяться без предварительного уведомления об этом. Компания S2Tech Europe отклоняет любую ответственность со своей стороны за возможные ошибки в руководстве, а также в случае нанесения возможного случайного прямого или косвенного ущерба, как...

- Página 22 Примечание: Содержащаяся в данном руководстве по эксплуатации информация может изменяться без предварительного уведомления об этом. Компания S2Tech Europe отклоняет любую ответственность со своей стороны за возможные ошибки в руководстве, а также в случае нанесения возможного случайного прямого или косвенного ущерба, как...

- Página 23 Примечание: Содержащаяся в данном руководстве по эксплуатации информация может изменяться без предварительного уведомления об этом. Компания S2Tech Europe отклоняет любую ответственность со своей стороны за возможные ошибки в руководстве, а также в случае нанесения возможного случайного прямого или косвенного ущерба, как...

- Página 24 Примечание: Содержащаяся в данном руководстве по эксплуатации информация может изменяться без предварительного уведомления об этом. Компания S2Tech Europe отклоняет любую ответственность со своей стороны за возможные ошибки в руководстве, а также в случае нанесения возможного случайного прямого или косвенного ущерба, как...