Aspen Pumps mini orange Manual De Instalación Y Mantenimiento

Ocultar thumbs

Ver también para mini orange:

- Manual del usario (20 páginas) ,

- Manual de instalación y mantenimiento (15 páginas) ,

- Manual del usuario (11 páginas)

Tabla de contenido

Publicidad

Enlaces rápidos

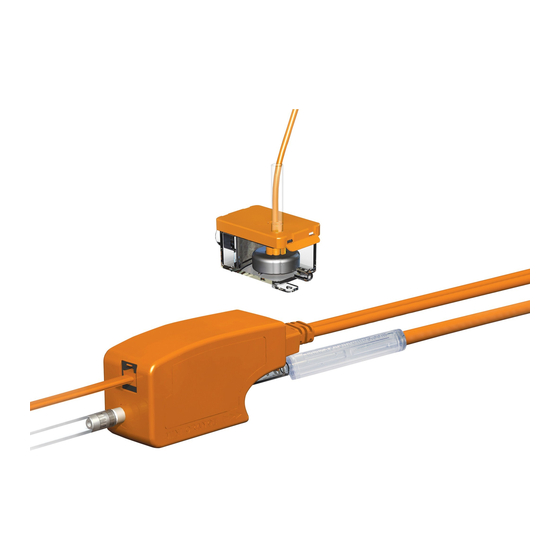

mini & maxi orange pump / bomba

INSTallaTIoN & maINTeNaNce maNual / maNual De INSTalacIÓN Y maNTeNImIeNTo

for mINI oraNge moDelS / moDeloS: aSP-mo-115, aSP-mo-230, aSP-mo-lg24

Thank you for buying your new mini / maxi orange Pump. This manual provides complete instructions for

installation and maintenance which should be carefully followed. Please record following information for future

reference: / agradecemos su compra de la nueva bomba mini o maxi orange. Éste manual proporciona las

instrucciones completas que deben de seguirse cuidadosemente para la correcta instalacion y mantenimiento de la

bomba. Anote la información siguente para una referencia futura.

Serial number:

Número de serie:

Date installed:

Fecha de instalación:

Imported and Distributed by: / Importado y distributado para:

1244 Davol Street, Fall River MA 02720 Tel: 800-324-7832 Fax: 508 673-0115 email:info@airtecproducts.com

www.airtecproducts.com

Product Warranty

The manufacturer disclaims all implied and express warranties, including the implied warranty of merchantability and the implied warranty of fitness for a particular purpose,

except as follows: This condensate product purchased by you concurrently is unconditionally warranteed to be free from defects in material and workmanship under normal use for a period of two years

from date of purchase, providing it is installed and operated strictly in accordance with the manufacturer's installation instructions. If the product is found to be defect or otherwise fails in normal use,

you may return it for replacement. All freight charges for the return of the product shall be borne by you. The manufacturer will pay outgoing freight charges for the replacement product. Defective

product returned to the factory prepaid will be repaired or replaced free of charge. Replacement product will, to the extent such product is then available in the manufacturer's inventory, be of a

similar type of color and kind. Manufacturer retains the right to substitute product if the replacement product does not conform in terms of color, type and specifications to the original product if no

longer available. This warranty does not cover replacement labor or any cost, claim or incident to any defect nor does it cover any consequential damages. The sole liability of the manufacturer under

this warranty is limited to the replacement of defective product. Product damaged by improper use, accident, neglect, alteration, abuse or improper installation is excluded from this warranty.

Manufactured by: Aspen Pumps Apex Way Hailsham East Sussex BN27 3WA United Kingdom

website: www.aspenpumps.com

for maxI oraNge moDelS / moDeloS: aSP-maxo-115 & aSP-maxo-230

• Designed for installation above a false ceiling where possible, inside casing of

minisplit evaporator unit where space permits or inside lineset cover /

Diseñada para instalar sobre un techo falso donde sea posible, dentro del

gabinete del evaporador donde lo permita el espacio o dentro de la cubierta

• Quietly and reliably pump condensate to a maximum height of 26 feet (Mini

Orange) or 65 feet (Maxi Orange) / Bombean el agua condensado hasta una altura

de 26 pies (Mini Orange) o 65 pies (Maxi Orange) de manera silenciosa y confiables

• 2 reservoir options supplied for installation flexibility / se ofrecen 2 opciones

Operating voltage:

Voltaje operativo:

Location of pump:

Ubicación de la bomba:

• Quick and easy to install / Rápido y fácil de instalar

de depósito para dar más flexibilidad a la instalación

de tuberia de cobre

ASPEN/04/10 ZCO891

Publicidad

Tabla de contenido

Resumen de contenidos para Aspen Pumps mini orange

- Página 1 Orange) or 65 feet (Maxi Orange) / Bombean el agua condensado hasta una altura de 26 pies (Mini Orange) o 65 pies (Maxi Orange) de manera silenciosa y confiables • 2 reservoir options supplied for installation flexibility / se ofrecen 2 opciones de depósito para dar más flexibilidad a la instalación...

-

Página 2: Technical Data / Datos Técnicos

Mini Orange: 115V CA 0.18A 15w 60HZ • ETL® 230V CA 0.11A 16w 60HZ • CAPACIDAD: Mini Orange: 3.7 GPH @ cero pies 24V CA 0.7A 16w 60HZ de carga, 0.8 GPH @ 26 pies de carga hidrostatica Maxi Orange: 115V CA 0.28A 21w 60HZ Maxi Orange: 10 GPH @ cero pies de carga, 230V CA 0.15A 21w 60HZ... -

Página 3: Kit Includes / El Paquete Incluye

Kit includes / El paquete incluye NOTE: Check that all components are present before starting installation. NOTA: Comprobar que estén presentes todos los componentes antes de iniciar la instalación. Pump unit Drain Hose Adaptor Inline reservoir with lid & sensor cable, 4 12”... -

Página 4: Mini Orange Performance Graphs Graficas De Comportamiento Mini Orange

Mini Orange Performance Graphs Graficas de comportamiento Mini Orange WITH CONSTANT 3 FOOT SUCTION LIFT CON EXTRACCI” Ó N DE SUCCIÓN WITH NO SUCTION LIFT / CONSTANTE DE 3 PIES SIN EXTRACCIÓ” N DE SUCCI” Ó N US GALLONS PER HOUR /... -

Página 5: Power Supply

Important notes / Notas importantes SIZING OF DISCHARGE HOSE USING DISCHARGE HOSE OTHER THAN SIZE SPECIFIED wILL MATERIALLy AFFECT PUBLISHED DATA AND MAy RESULT IN LOwER PERFORMANCE. DIMENSIONAMIENTO DE LA MANGUERA DE DESCARGA EL USO DE UNA MANGUERA DE DESCARGA DE DIMENSIONES DIFERENTES A LAS RECOMENDADAS AFECTARÁ SIGNIFICATIVAMENTE LOS DATOS PUBLICADOS ASI COMO EL DESEMPEÑO. -

Página 6: Checklist / Lista De Verificación

PREVENTION OF SIPHONING Ensure that end of discharge hose is higher than water level in evaporator drain pan. If condensate discharge point must be lower than drainpan then 1/4” discharge hose from pump must empty into a larger diameter drain pipe at a higher level than drainpan. THIS JOINT MUST INCORPORATE AN AIR BREAK TO PREVENT SIPHONING. -

Página 7: Product Safety / Seguridad Del Producto

• Acceptable for indoor use only. • Non-submersible pumps. • PrecaucIÓN : Las bombas Mini Orange y Maxi Orange han sido evaluada para utilizarse solamente con agua. • aDVerTeNcIa : Peligro de descarga eléctrica. Estas bombas no han sido probada en aplicaciones de piscinas o zonas marinas. - Página 8 Installation – reservoir / Instalación – depósito Select correct reservoir type A inline or B panmount. Seleccione el tipo de depósito correcto en lÌnea A o B montaje en bandeja de desagüe. eVaPoraTor coIl / SerPeNTÍN Del eVaPoraDor CONDENSATE DRAIN TRAy / BANDEJA DE DESAGÜE DEL CONDENSADO Insert filter into reservoir selected.

- Página 9 Installation – reservoir / Instalación – depósito Check that float is in correct position on shaft, with magnet facing upwards and that filter is in place. DO NOT OPERATE THIS PUMP wITHOUT FILTER. Fit lid onto reservoir and clip firmly in place. Comprobar que el flotador esté...

- Página 10 Installation – Drain Hose, Pump & Wiring Instalación – Manguera de Drenaje, Bomba y Cableado Install pump unit in evaporator casing, above ceiling or inside lineset cover. NOTE: Sound deadening material must be used between pump and any hard surface in evaporator, ceiling or lineset cover to eliminate vibration and reduce noise.

- Página 11 NO LA USE UNA MANGUERA DE DESCARGA MAS GRANDE DE ¼” de d.i. Direccione la manguera de descarga a un drenaje appropriado. MINI ORANGE: MAxIMUM 26FT / MINI ORANGE MÁxIMO 26 PIES MAxI ORANGE: MAxIMUM 49FT / MAxI ORANGE MÁxIMO 49 PIES...

- Página 12 Installation – Drain Hose, Pump & Wiring Instalación – Manguera de Drenaje, Bomba y Cableado Wiring / Cableado CONFIRM MAIN POWER SUPPLY IS ISOLATED. Thread power cable through evaporator to terminate at incoming power terminal. Connect power and overflow alarm wires according to relevant diagram and attach warning label to front of terminal cover.

- Página 13 115V ac / ca mINI oraNge 208/230V ac / ca white blanco rojo incoming 115V AV incoming 208/230V AC power terminals power terminals black negro black negro permanently live permanently live entrantes de 115V CA entrantes de 208/230V CA...

- Página 14 Installation – Drain Hose, Pump & Wiring Instalación – Manguera de Drenaje, Bomba y Cableado PUMP MAY TEST PUMP OPERATION By POURING wATER INTO EVAPORATOR DRAIN PAN. BE NOISY ONLY WHILE AIR IS EXPELLED DURING INITIAL START-UP. IF NOISE PERSISTS AFTER START-UP, THIS INDICATES A SIPHONING OR AIR LEAKAGE PROBLEM, DO NOT RUN PUMP! CHECK THAT ALL CONNECTIONS ARE wATERTIGHT TO ELIMINATE AIR IN HOSES.

-

Página 15: Troubleshooting / Localización De Averías

before SerVIcINg or TroubleSHooTINg DIScoNNecT PumP from PoWer SuPPlY. aNTeS De Dar SerVIcIo o localIZar aVerIaS DeScoNecTe la fueNTe De alImeNTacIÓN De la bomba. Servicing / Servicio This pump, like all mechanical equipment, requires periodic and regular maintenance. At 6 month intervals, the reservoir, filter and float should be thoroughly cleaned with an antibacterial cleansing solution and all hoses should be checked for leaks. - Página 17 Guidelines for Installation of Discharge Hosing In order to fully understand the operatIon of these pumps, It Is necessary to understand some of theIr basIc prIncIples of operatIon: All minisplit piston pumps share some common characteristics: 1. they are self priming. 2.

-

Página 21: Gua Para La Instalación De La Manguera De Descarga

Gua para la Instalación de la Manguera de Descarga con el objetIvo de entender completamente la operacIón de estas bombas, es necesarIo entender algunos de sus prIncIpIos básIcos de operacIón: Todas las bombas de pistón para minisplit comparten algunas características comunes: 1. - Página 24 Airtec hvac accessory product lIne airtec Air diffusers eZ-trap Condensate traps & switches fortress Lineset covers slimduct Lineset covers aspen Mini condensate pumps novent Locking refrigerant caps big foot AC rooftop mounting system airtec AC equipment mounting slimduct Condensate drain hose airtec products corp.